Portable, reliable

EQiblygasia

0

30

12.08 02:21

Using the Balanset-1A Instrument

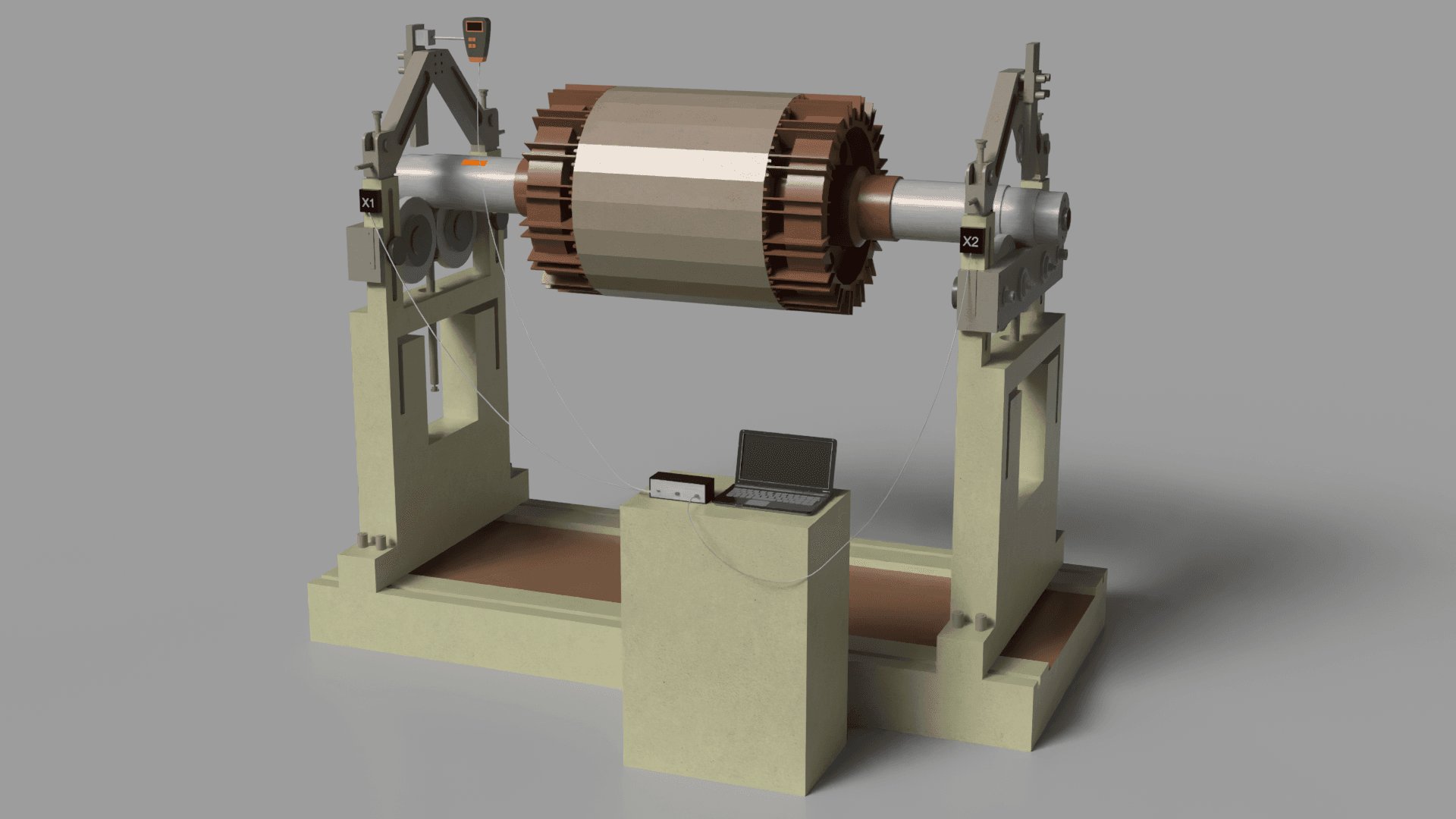

Getting the Equipment Ready

- Ensure the instrument is complete with all necessary components: vibration transducers, laser tachometer, magnetic stand, software, and other accessories.

- Connect the device to your PC using the USB interface and confirm the software installation.

Sensor Installation

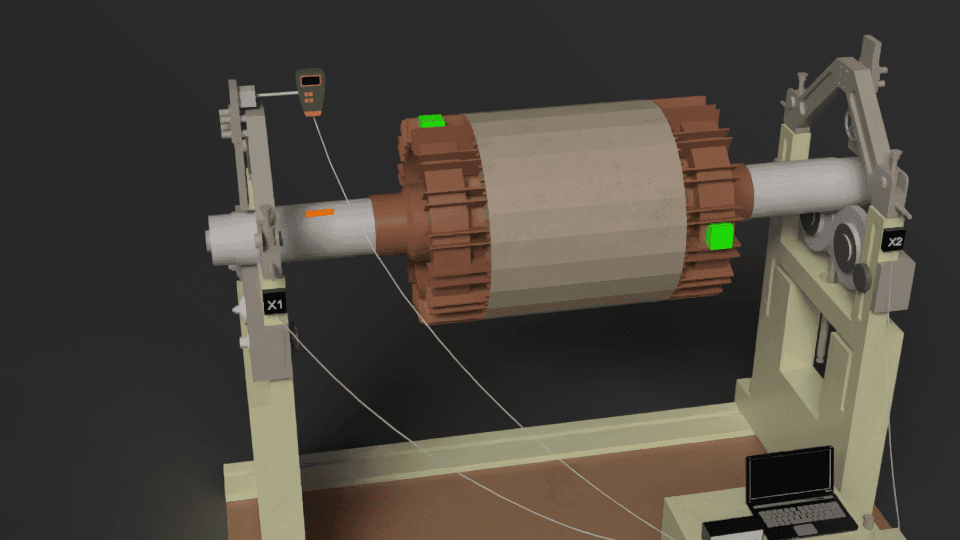

- Fix the accelerometers securely to the machine's structure in locations where vibrations are most prominent, ideally near the bearings.

- Position the laser tachometer (phase angle sensor) so that it is aimed at the rotor. Attach reflective tape to the rotor for accurate phase angle reading.

Software Startup

- Open the Balanset application on your PC.

- Choose the correct balancing method (single or two-plane) according to the rotor configuration and the balancing task.

- Operate the rotor at its intended working speed.

- The software will measure the vibration level, rotational speed, and phase angle. This data establishes the current imbalance condition.

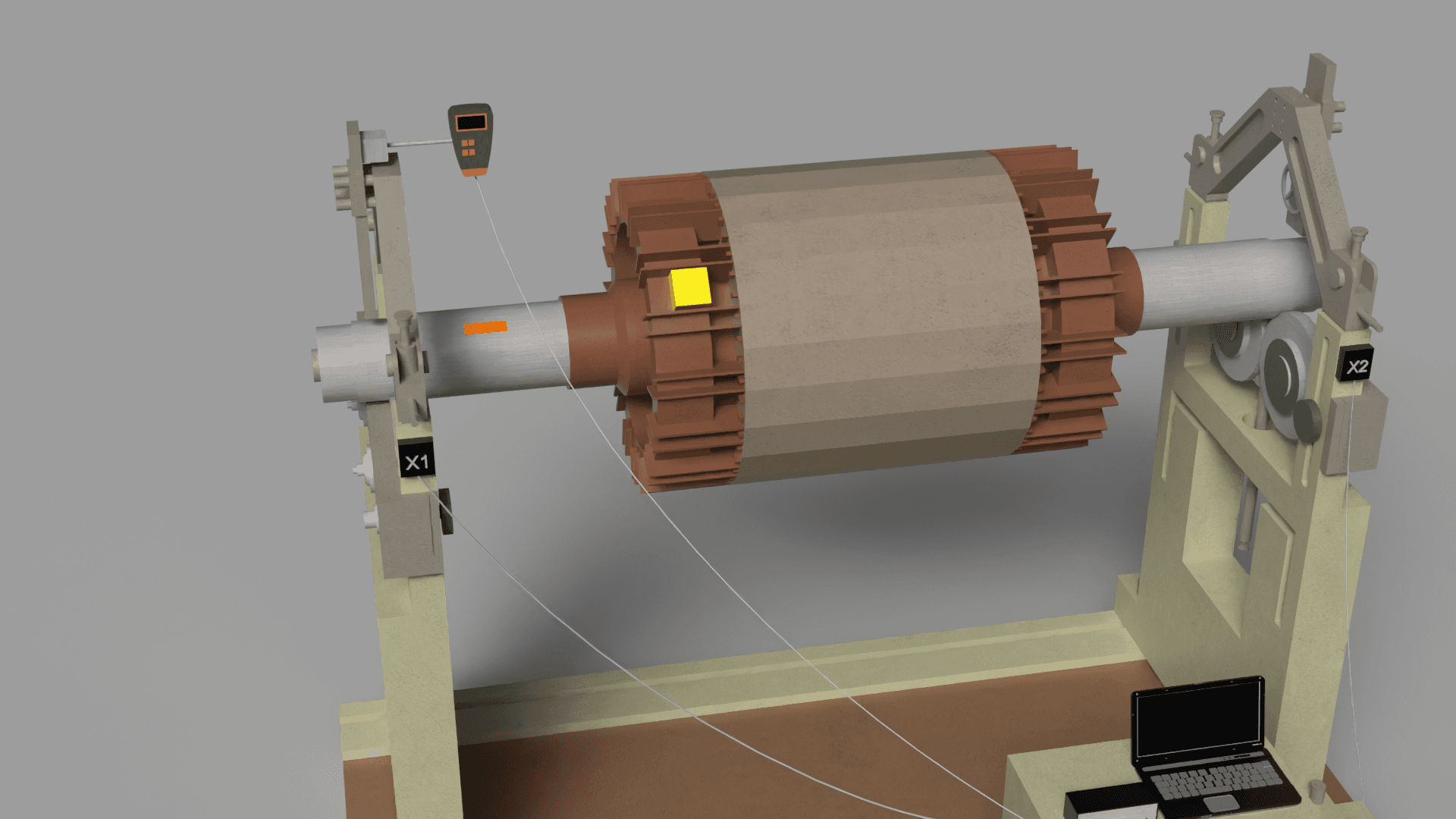

Attaching the Trial Weight

- Halt the rotation and mount a test weight at a designated position on the rotor, with the weight's value entered into the software (usually in grams).

- Resume rotor operation, and the program will capture the resulting changes in vibration amplitude and phase.

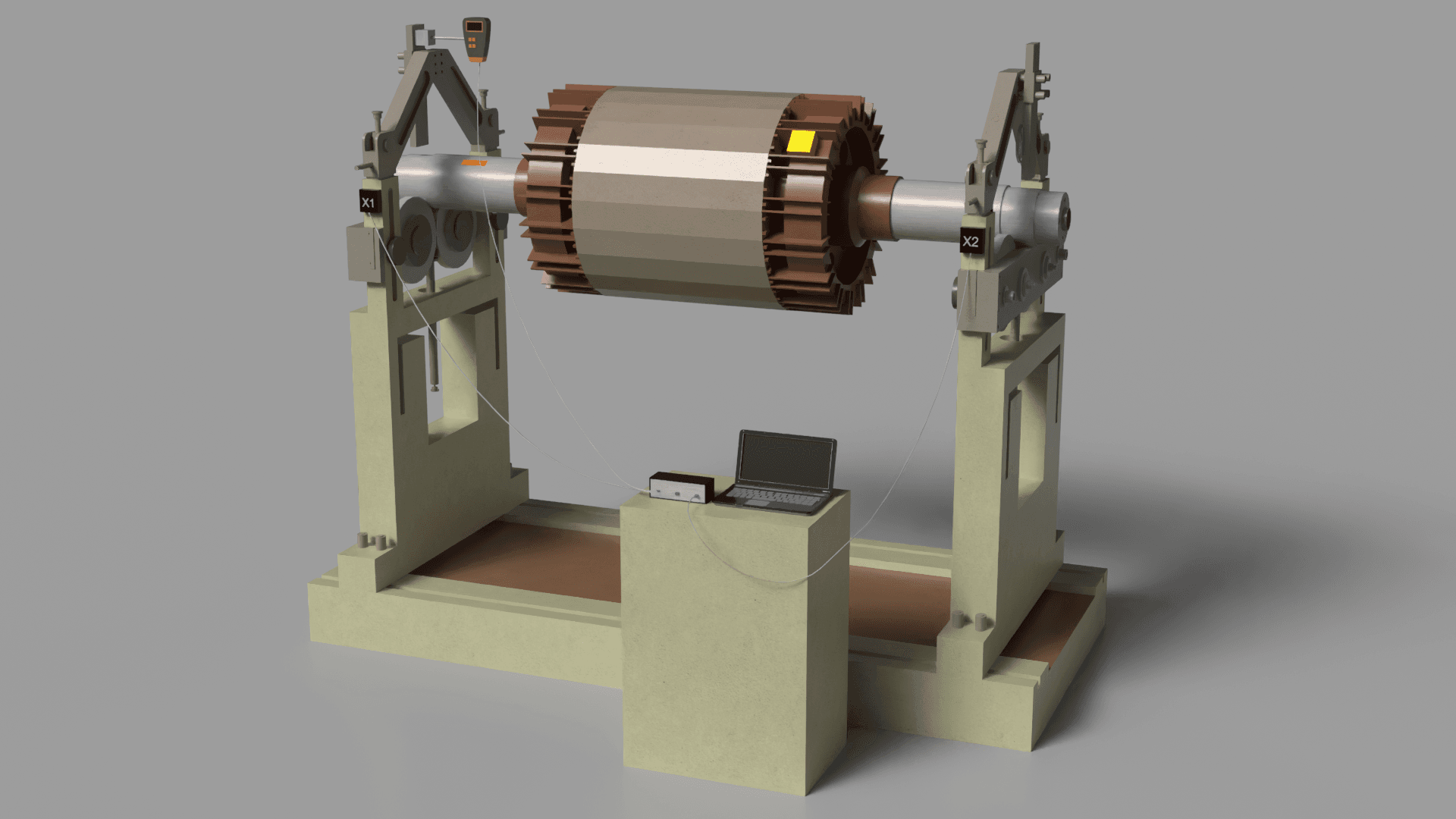

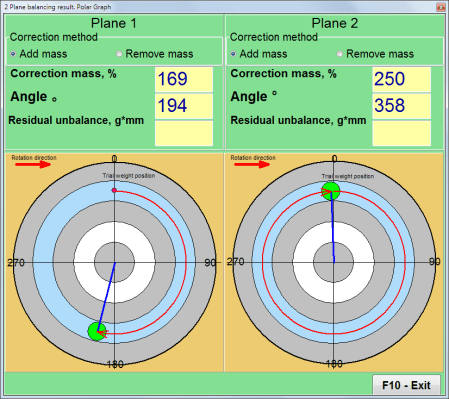

Computing the Compensating Weight

- Using the acquired measurements, the program automatically determines the required corrective weight's mass and angular position.

- These parameters are displayed on the screen as numerical data and graphs.

Mounting the Compensating Weight

- Install the correction weight on the rotor according to the software's calculations.

- You can conduct interim measurements to confirm that the imbalance is decreasing as expected.

Validation and Conclusion of the Balancing Process

- With the compensating weight attached, operate the rotor and assess the level of any residual vibration.

- The balancing procedure is finished if the remaining vibration is within the permissible limits specified in ISO 1940.

- If the vibration level remains high, repeat the process with further weight adjustments.

Creating a Balancing Report

- All balancing results are logged and archived within the software, from which you can produce a printable report summarizing the vibration levels, compensating weight, and its installation position.

Post-Balancing Checklist

- Double-check that all weights and sensors are securely fastened.

- Check that the rotor's rotation is smooth and free from undue noise or vibration.

- If the rotor operates within a larger assembly, check the functionality and interplay of all interconnected parts.

Following this procedure enables accurate balancing, minimizes vibration, and prolongs the service life of the equipment.

Instagram: https://www.instagram.com/vibromera_ou/ Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL Our website about Balancing of drilling machine rotors